When you are working in manufacturing or quality control, you must ensure that the things they make satisfy the exact demands of their customers. One technique to do so is to conduct a first article inspection (FAI).

When an authorized person — usually the supplier or a third-party inspector with a laboratory and specialized measuring equipment — takes one or more components from the first production run, it is called a first article inspection. They then compare them to the client’s requirements to ensure that they are identical. Because the purchase order contains that information, it serves as the primary reference point during the inspection.

Contrary to popular belief, an FAI does not always entail inspecting the first pieces off the assembly line. It includes selecting them from the initial batch, though the FAI persons frequently choose them at random.

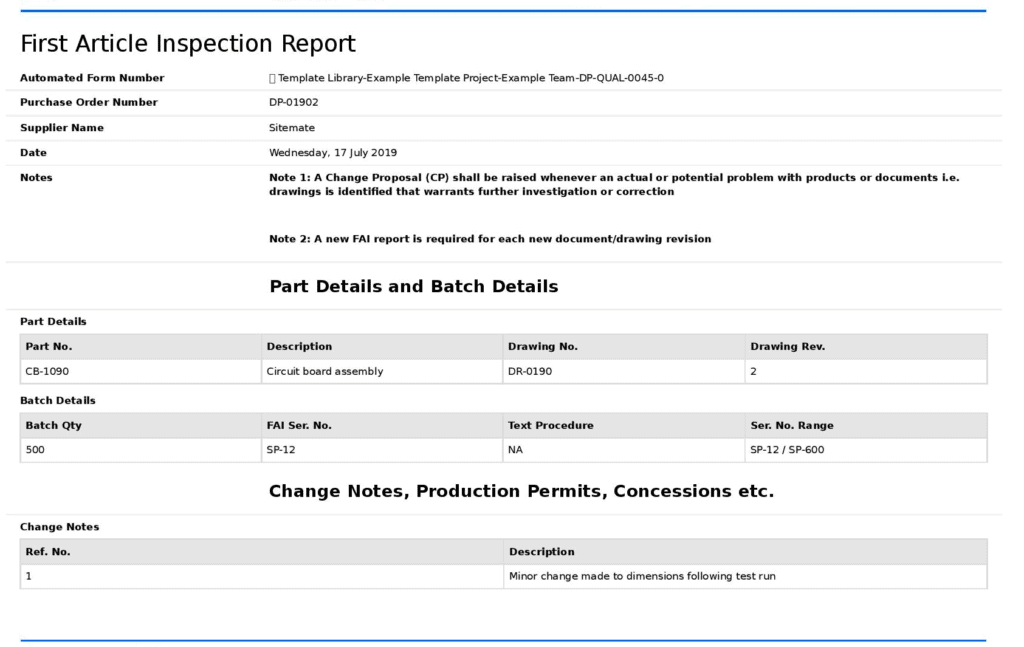

Inspectors will make use of a variety of FAI inputs. Specifically, a 2D design or 3D model and material and process specification will be developed. After the inspection is complete, generate a first article inspection report, including a drawing, verified measurements of the component’s elements, and perhaps some additional checklist items that the customer may require.

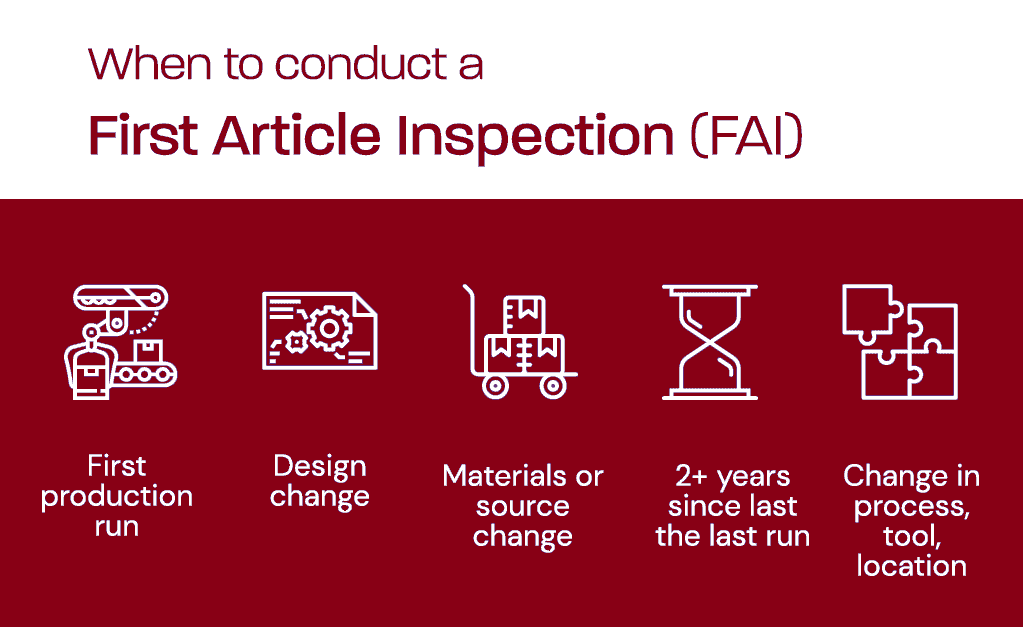

When is a First Article Inspection Conducted?

After a producer and buyer have concluded a purchase order contract, a first article inspection is usually required. Because a first item inspection is a manufacturing procedure that verifies the quality and correctness of a product or part, it should be performed after all designs have been completed. A first article inspection can be executed during the initial production run once a plan has been approved and the appropriate production modes have been selected.

Aside from performing an FAI during the initial production run or when the design of a part changes, there are various other instances in which it is appropriate to do so.

When a production pause of two years or more occurs, a first article inspection should be part of the manufacturing process when they resume.

Additionally, first article inspections should be performed if any changes are made to the materials, sourcing, process, tools, or location. These checks verify that the adjustments had no negative impact on the product’s functioning, size, or quality.

When a part or product undergoes design revisions, a delta FAI (also known as a partial FAI) arises. In this case, the report breaks down the differences between the most recent version and the original FAI.

If you have the opportunity to go to your supplier’s or manufacturer’s plant in another country, it’s a good idea to do a first article inspection while you’re there.

What is the need for First Article Inspections?

First article inspections are typically connected with specific industries such as aerospace, automobile, electronic devices, medical devices, and so on. Quality and accuracy of production parts are critical in such businesses. During manufacture, car parts or components for a plane engine must be closely checked to ensure that each item follows design plans, conforms with safety rules, and can perform the job for which it was built.

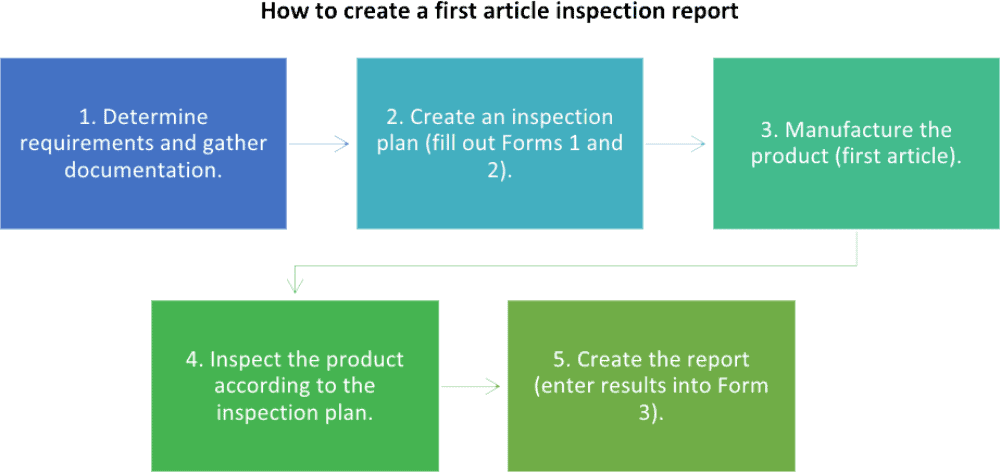

How to Make a First Article Inspection Report

Step 1: Plan ahead of time for your FAI

Gather the following documents for your First Article Inspection before you begin:

- Drawings for engineers

- Data sets for defining digital products

- Materials list/bill of materials

- Specifications

- Planning/routing/traveler/work order in manufacturing

- Information on the source/supplier

Step 2: Formulate an Inspection Plan

The formulation of an inspection plan is the second phase. It is made up of the following steps.

- Firstly with a balloon number, identify the need that will be inspected. Furthermore, f Fill out the AS9102 forms; the first is for numerical accountability, and the second is for product accountability. The Bill of Materials and Specifications list will provide you with the information you need to complete the form.

- Make a list of the balloon’s reference position.

- Make a list of the criteria, which should include the measuring units as well as any other requirements that vary depending on tolerances.

- Finally, make a list of the classifications, which should include critical, major, and key criteria.

Step 3: Making the Product

- The product is manufactured in the third phase.

- Develop the product and ensure that the entire process and inspection results are appropriately documented and recorded.

- Remember that the first article is a randomly selected item from the initial production run, not necessarily the first good manufactured.

- Maintain a record of authorized inspection tools so that they can be traced back to the person who used them to precisely measure the production process.

Step 4: Collecting Data

The data from the entire procedure is gathered in the fourth stage.

Step 5: Make a Report

The creation of the report is the fifth phase. You need to fill up the form with the measurement data, making sure to use qualified equipment. Ascertain that the data is non-conforming. Lastly, make a report on the functional test.

The Benefits of First Article Inspections:

Manufacturers and organizations would waste a substantial amount of resources if they continued with early manufacturing methods with faulty or inaccurate parts without a first article check. They won’t be able to meet kanban. To put it another way, for enterprises in these industries, a first article inspection is a must. Similarly, industries such as aerospace and medical devices have their own set of procedures that must be followed, which usually include some type of first item inspection.

Before moving forward with manufacturing and completing the purchase order, conduct a thorough inspection to ensure that everything is in working order with your equipment, settings, processes, and supplies. By establishing an inspection, you are not only saving money. But you are also decreasing waste in the business and speeding up production by immediately identifying and correcting faults.

What Happens During an FAI?

To ensure completeness, a person performing FAI has a document — commonly a checklist — that they refer to throughout the first article inspection procedures. This person additionally compares the produced parts to the requirements using specialized instruments called coordinate measuring machines or simply stated as CMMs. It’s a test to see if there is any variation. If there are any differences, they’ll see if they’re within the client’s tolerances.

For quality control inspections, CMMs are the most precise measurement equipment available. Within that product category, however, there are various varieties. Fixed CMMs are, for example, the most common choice among quality control managers.

They are capable of measuring any product attribute and are particularly useful for complex parts. Portable CMMs are available for components that are too large or bulky to be moved off the manufacturing floor.

The person in charge of the FAI checks the components for faults that cause them to fall short of the standards with their measuring tools. The use of inappropriate materials, inadequate material quality, and poorly set processing equipment are some of the most typical issues discovered during the first article inspection.

The Purpose of a First Article Inspection in Manufacturing:

An engineering review is performed on an item before it is put into production in a CNC machine shop. The first article of the part is manufactured once a design is considered manufacturable and the requisite materials are received. When the part is finished, it will go through the first article inspection, which will check for the following:

- Verify: Firstly, the manufacturer checks that the initial part made meets the customer’s criteria. Machine shops use electronic data for machine equipment as well as drawing documentation that describes the product’s size, shape, and specifications. Quality inspections and FAI inspections are conducted against a two-dimensional print of the component design provided by the client. Which frequently includes additional information about tolerances for specific characteristics of the part.

- Documentation: For two reasons, the inspection of the first article shall be documented. To begin, the manufacturer will rely on the first article inspection report for frequent audits to confirm that the part’s production matches the first article. Second, first-article inspections for parts built for certain industries, such as aerospace, must be documented in accordance with established criteria.

- Confirm: The first article inspection validates that the part meets the basic standards and allows for additional customer communication. A first item inspection report, for example, will be used by the machine shop to check or change the part’s design parameters as needed. In these cases, the FAI goes beyond a simple pass/fail report and becomes a tool for fine-tuning specifications to meet the needs of the customer.

An Important Step in the Quality Control Process:

When it comes to determining quality, the first article examination is surely not the sole test to do. It can, nevertheless, be critical during the fabrication of specific components. An FAI can help a client feel sure that a supplier can meet their needs without making costly mistakes.