Updated: 19 November 2021

The Meaning of AQL

Literally speaking, AQL standards for Acceptable Quality Limit: this means the worst quality that is tolerable or acceptable in a given sample of products according to the ISO 2859-1. This is basically the maximum amount of goods that an inspection team or buyer would accept that are of sub-standard quality.

if the number of defected goods exceeds this number, then the entire batch of goods is rejected. AQL levels are perhaps most important for importers who are not physically present at the manufacturing site to oversee production and thus have to resort to inspection teams to carry out quality control on their behalf.

By setting different AQLs for critical, major, and minor defects, importers can ensure that each class of product is treated according to the standards that it requires.

To breakdown the meaning of AQL in even simpler terms, consider the following example:

If an importer writes to his supplier that the AQL is 2%, this means that if defective goods represent more than 2% of the batch produced, then the order will not be accepted. The AQL varies for different kinds of goods and according to the importer’s demands.

The AQL Calculator

For many users the AQL table may seem intimidating and complex; this is where our calculator makes the process a whole lot easier to save you time and effort. Simply fill in the calculator to find out what number of samples will be optimal for you. As well as the number of major and minor defects that you should tolerate on the basis of the specifications that you have provided.

What is AQL Table?

AQL is a measure that is implemented to items and explained in ISO 2859-1 as the “quality level that is the worst tolerable”. It explains how many defective parts will be accepted during the phase of random sampling quality inspections. It is normally stated as a percentage or ratio of the number of defects as compared to the total quantity.

The AQL is the worst quality level that is tolerable for an item that varies from item to item. Items that are more prone to higher health risks will have a lower AQL. Batches of items that do not fulfill the AQL, usually depending on a percentage measurement, are rejected when tested during pre-shipment inspections.

Major Defects in AQL

Following are the Major Defects that People Often Face in AQL:

- Critical Defects: These defects are accepted when they are problematic and cause harm to the user. These are considered as 0% AQL.

- Major Defects: Tese defects are not acceptable by the end-users, as they are most probably the cause of failure. The AQL for major defects is 2.5%.

- Minor Defects: Defects are not likely to lessen materially the usability of the item for its planned purpose but that varies from certain standards; some end users will still purchase such items. The AQL for minor defects is 4%.

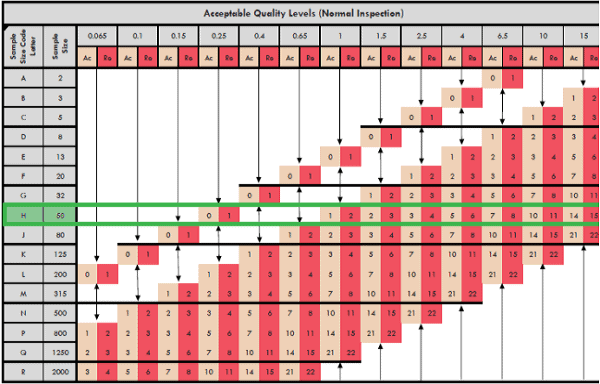

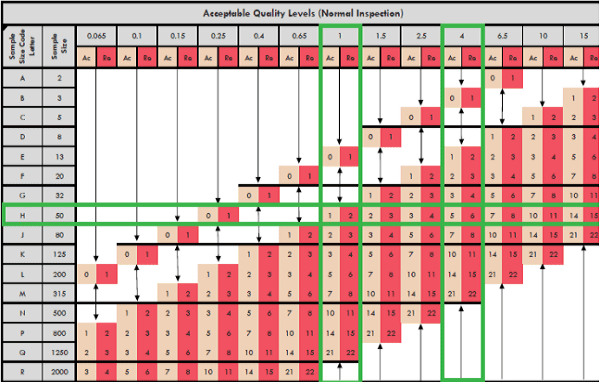

AQL Table

The AQL table is one of the most commonly used tools by quality inspectors to determine the following:

- The optimal number of products to be inspected (sample size)

- Choosing the maximum number of defective goods that can be accepted in a shipment

Why do you Require an Objective Measurement of Quality?

Because most products require manual input and some sort of labor work. It is highly unlikely to expect any batch to have each and every product that is in line with the specifications and requirements asked from it; there are bound to be a few defective products in every batch of products that you inspect.

Also, keep in mind that even if the manufacturer claims that he has visually checked all products and found no defects. It is still worthwhile for you to carry out a detailed inspection of the products because there exist several defects that are visible only through a thorough inspection of the internal parts.

But the question arises, how do you exactly set the limit for the number of defective goods that you will accept in a batch? What kind of quality defects can you tolerate, and how many? Naturally, if you leave this all to intuition then you would have different results on every batch that you inspect. Therefore, it is extremely important to quantify the measurement of quality and that is where AQL helps you.

The ANSI ASQ Z1.4 AQL Table for Sampling Plans

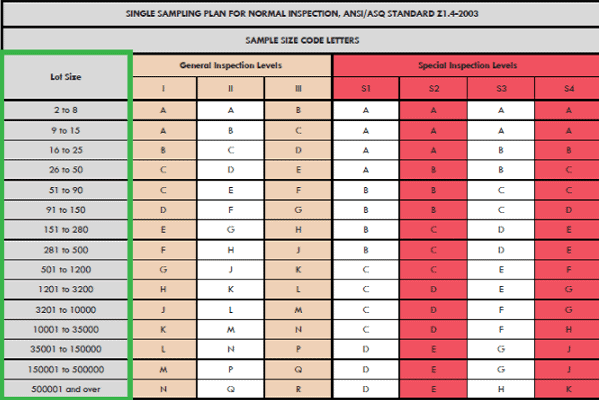

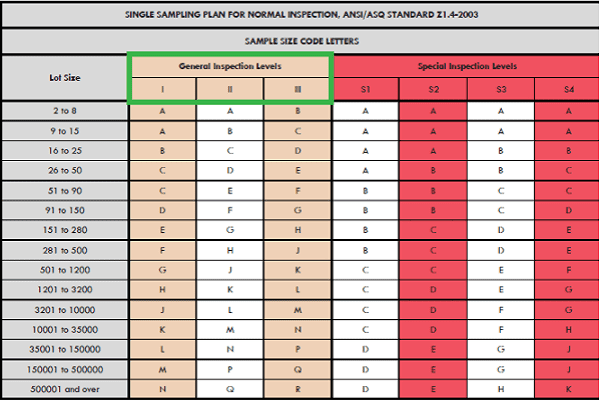

There are five major sections of the single-sampling ANSI Z1 4 table: inspection levels, lot and sample sizes, code letters, level of acceptable quality, and acceptance and rejection points. Following are the criteria through which sampling is done, so have a look and find out.

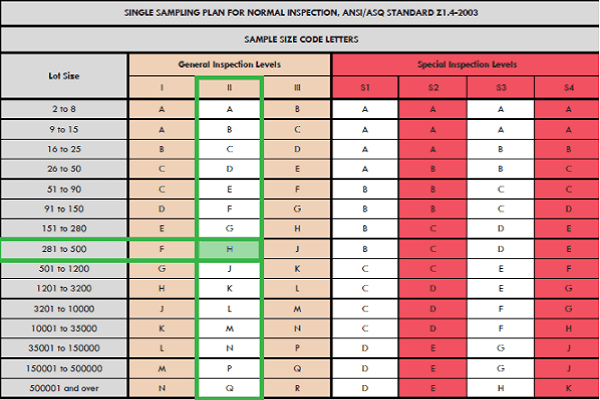

Lot Size

The lot size is your initial point for utilizing the ANSI Z1.4 table, shown by a variety of order quantities shown in units. Using the AQL sampling plan tables is easy to pick the lot size range based upon your total order quantity. For example, if we say that you have an order quantity of 300 tablet PCs. Then you’d utilize the lot size range of 281 to 500 units.

Inspection Level

The inspection level one picks a significant feature of the ANSI sampling plan and the criteria of your product inspection. It is significant to choose it cautiously by keeping in mind the expectations of customers, product quality standards, obstacles interlinked with time and budget. It is further divided into two levels: general inspection levels and the other is specific inspection levels.

General Inspection Levels

It includes inspecting the item manually to look for quality flaws and issues and doing any on-site tests and checks that manage the primary sample size. General inspection levels are further segmented into three smaller columns “GI,” “GII,” and “GIII,” each with its own set of sample size code letters corresponding to specific lot size ranges.

GI is linked with the smallest sample size. By keeping in mind the “budget option, you may choose GI if you’re tight on budget and only want a cursory inspection of an order. GIII is the toughest standard and needs inspecting a bigger sample size, giving a more thorough assessment of an order’s whole quality.

The issue with GIII is that a bigger sample size needs more time to examine, which makes it a costly option. GII is the middle option and is the one that is frequently used in the ANSI sampling plans for examining consumer products.

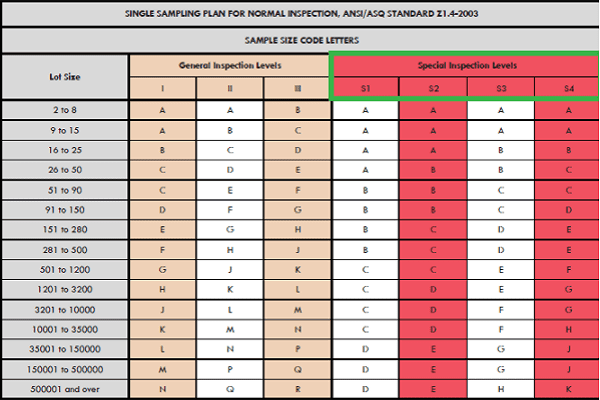

Specific Inspection Levels

It is done for special product tests that should be done on a comparatively small sample of units. Smaller sample sizes are typically done based on tests like the ones that are destructive to the product, costly, or time-consuming to deal with, or plan to yield similar results across all units one after another.

As an example, you can think of an item’s test that can be destructive and implemented to most of the items. Such as PCs and tablets is the carton drop test. It is not significant to check printing adhesion on many tablets since the print implementation process rarely differs between units of a similar SKU.

Sample Size and Code Letters

Here sample sizes are shown by code letters on the initial part of the ANSI Z1.4 table. By going for the row of the lot size to the selected inspection level, you’ll see a corresponding code letter. The sample size is decided by the lot size can at times be really big or too small for the selected AQL.

You may need a bigger sample size if by chance you pick a relatively low AQL. The lower your tolerance for flaws, the more units you’ll require to examine to reasonably assume the average quality of the complete order. And if the suitable sample size equals or surpasses your lot size, you’ll examine 100 percent of the order.

Acceptance Quality Levels

At times it is called “acceptable quality limits”, AQLs vary from 0 to 15 percent or more, with 0 implying the lesser tolerance for flaws. Importers’ tolerance for smaller issues tends to be more extreme than that for huge and complicated flaws. That’s the reason they commonly pick a dissimilar AQL for all of these categories of product defects.

Selecting an AQL isn’t always as simple as choosing whatever QC experts or other importers suggest. It doesn’t mean that whatsoever working for a single importer will also be beneficial for you. There are many factors to keep in mind when selecting the finest AQL for your conditions. Such As: What level of quality your supplier thinks is suitable and has planned to fulfill, the exit-factory date, and the worth of the products in question.

Acceptance and Rejection Points

The former point implies the highest number of flaws you’ll accept in the order. The latter explains the minimum number of flaws required to reject the order. For instance, an AQL of 0 for bigger flaws has a rejection point of 1 defect.

This means to say that if examiners find even one bigger flaw, the outcome of the inspection will fail. Both of these points increase as your tolerance for a flaw increases, relative to sample size.

The First Table: Sample Size Code Letters

How Do You Read this Table?

Looking at the code letter based upon your lot size, as well as keeping in mind the inspection (which in our case is assumed to be level ll), you choose the letter that corresponds to your lot size. Suppose the letter is ‘L’.

With your code letter being ‘L’, it shows that you would have to set aside a sample consisting of 200 pieces for inspection. Let’s also assume that you have set your AQL level at a standard of 2.5% for major defects and 4% for any minor defects.

These Criteria Yield the Following Limits:

Only accept the shipment if there are 10 or less than 10 products found with a major defect. Whereas the number of minor defects found in the sample should not exceed 14. If either of these two numbers is exceeded for the given category. Then you cannot accept the shipment without compromising on your AQL limits.

There may be a common misconception that the number of defective goods per sample is the sole or most important criteria for quality inspectors when approving or rejecting a sample. However, it is only one of the several factors that quality inspectors have to consider, sometimes referred to as ‘quality findings’ which determine the overall quality of the products.

These include, but are not limited to, the following:

- Whether the packaging is according to the required specifications of the importer, including factors such: as barcodes, inner packaging, cartons, and shipping marks.

- Visual conformance: if it can be visibly seen that the products are made in green color instead of orange, as ordered, then there need not be any quality inspection because all of the products are clearly in violation of the specifications. The shipment will be therefore rejected.

- The importer may instruct the manufacturer to carry out certain specific tests that will be pre-defined in the inspection checklist.

The Special Case of the AQL in Codex Standard Stan233 (Food Products)

For the special case of food items, in which inspection calls for opening the packaging and destroying the product so that it is no longer available for sale. The sample size selected is much smaller than in other cases. You will notice that the general approach is the same, but with certain changes that include reading the table based on the net weight of a unit of production.

Frequently Asked Questions Regarding the AQL

Questions regarding the general process of acceptance sampling:

Does This Mean that the Factory is Technically Allowed by me to Produce Some Defective Goods?

Well no, not in theory at least. To put it simply, AQL recognizes the fact that it is nearly impossible for a factory to churn out products that are 100% free of defects all the time. You are bound to come across cases where there are defective goods in the shipment; the AQL helps you decide the cutoff point beyond which you need not accept the shipment due to quality concerns.

So in practice, this means that you understand that the factory will most likely make some defects in a few of the products. But you wish to look at the greater picture and that is regarding the general quality level of the whole batch.

To Quote the ISO 2859 Regarding this Matter:

“Although individual lots with quality as bad as the acceptance quality limit may be accepted with fairly high probability. The designation of an acceptance quality limit does not suggest that this is a desirable quality level. Sampling schemes […] are designed to encourage suppliers to have process averages consistently better than the AQL.”

Is the AQL Level Applicable only for Finished Goods? Or can we use it to Inspect Incoming or Semi Finished Goods?

You can use the AQL for products in pretty much any stage of the production process as long as there exist clear criteria to differentiate a defective good from an approved one. As long as you have a clear distinction between products that are defected and approved. You’re good to go with this plan.

Common concerns about the underlying statistical techniques

Why Can’t we Just use a Certain Percentage to Inspect, Let’s Say 15%?

Well, to put it simply, it is recommended for a number of reasons. This is discouraged, as clause 4.3.3 of the ISO 2859-10 standard explains:

Ad hoc sampling should not be used because it will lead to unknown risks that may be too high. Furthermore, there is no formal basis for either the acceptance or non-acceptance of the lot. Examples of ad hoc sampling include the sampling of a fixed percentage of a lot or a convenience sample taken at haphazard times.

The reason also has to do with the fact that simply saying “check 15% of the batch” will give you varying results for the same confidence interval depending upon the number of total goods produced.